- Home

- >

- News

- >

- Industry News

- >

- The Development History of Turbochargers

The Development History of Turbochargers

From the Sky to the Road: The Dramatic Development of Turbochargers

The turbocharger, now a familiar sight under car hoods, boasts a history spanning over a century of engineering legend.

It began with the conquest of the skies and ultimately reshaped the power structure of land-based transportation.

I. Emergence and Birth: A Pioneer of Power in the Aviation Age (Early 20th Century)

The story of the turbocharger didn't begin with automobiles, but is inextricably linked to the fate of airplanes.

1905: The Foundation of the Concept

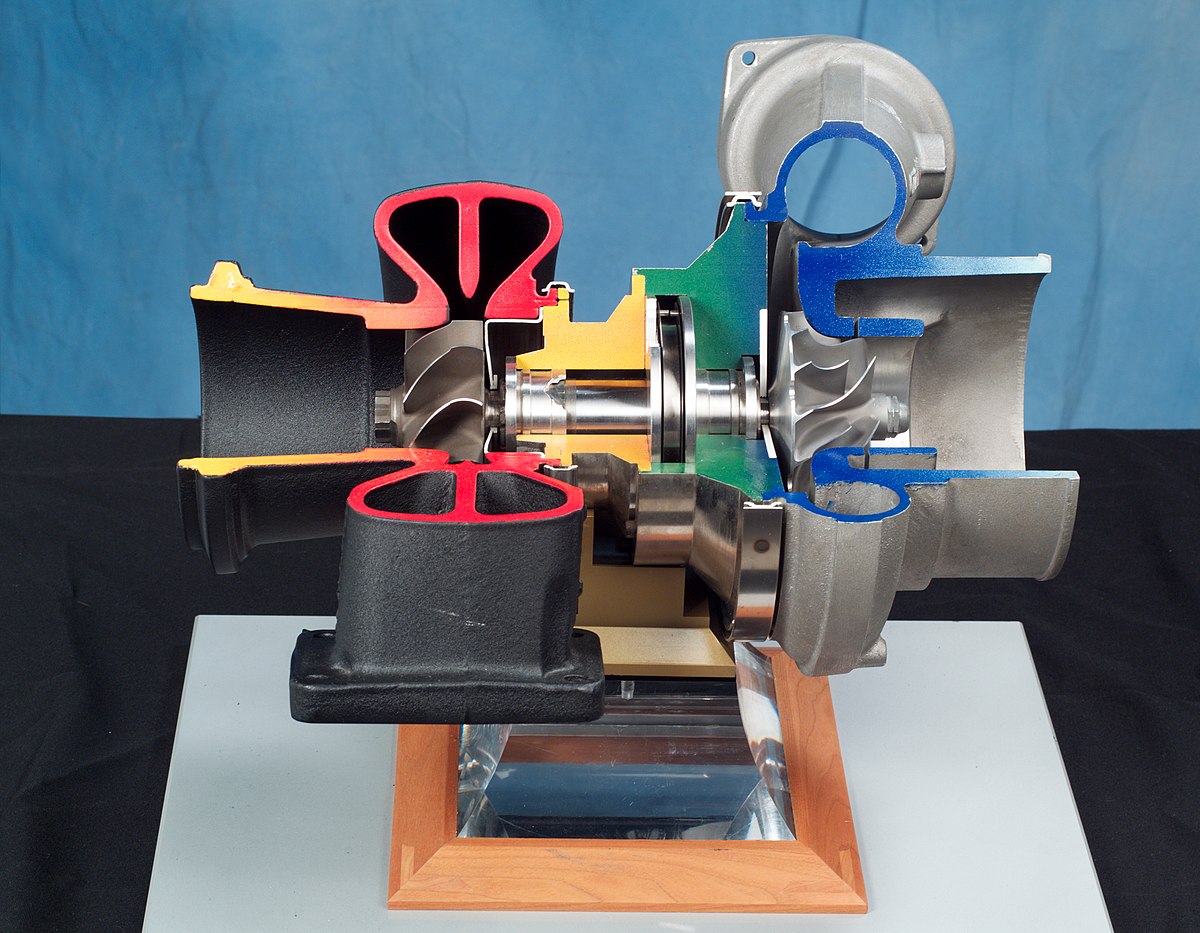

Swiss engineer Alfred Büchi first proposed the concept of a "turbocharger" and applied for a patent.

His initial design idea was to use the exhaust gases from the engine to drive a turbine,

which in turn drove a compressor to compress more air into the cylinders.

This was a groundbreaking concept, but the technology at the time made it difficult to realize.

World War I: The Key to Flying Higher

War is the cruelest and most effective catalyst for technology. At high altitudes,

the thin air causes a sharp drop in aircraft engine power. To solve this problem, Büchi's concept was urgently put into practice.

Companies like General Electric (GE) in the United States successfully developed practical turbochargers,

equipping fighter jets with powerful engines that maintained high-altitude performance, gaining a significant tactical advantage.

During this period, Garrett, leveraging its expertise in aviation thermal management systems, also began to enter this field,

laying the groundwork for its later success.

II. Transition and Exploration: From the Sky to the Ground (Mid-20th Century)

After World War II, turbocharging technology began seeking new applications.

**Early Application in Diesel Engines** Turbocharging technology first found its place in large diesel engines.

The massive diesel engines of ships, trains, and heavy trucks, due to their robust structure,

could better withstand the higher pressures of turbocharging, thus significantly improving efficiency and power.

For these commercial sectors that emphasized torque and durability, turbochargers demonstrated their immense economic value.

**Racing Track Testing Ground** Meanwhile, motorsports became the "extreme laboratory" for turbocharging technology.

Engineers discovered that in racing cars pursuing ultimate speed, turbocharging could "squeeze" out astonishing horsepower.

However, early turbochargers suffered from a severe "turbo lag" problem—a noticeable power gap between the driver pressing

the accelerator and the turbocharger fully engaging. This was a fatal flaw on the racetrack, where every second counts,

but it also spurred rapid technological iteration.

III. Rise and Popularization: Conquering the Passenger Car Market (1970s-1990s)

The two oil crises were the real catalysts for turbocharging technology to reach ordinary consumers.

Responding to the Crisis: Small Displacement, High Power

In the 1970s, the global oil crisis put large-displacement engines in a difficult position.

Automakers urgently needed a technology that could both reduce engine displacement to save fuel and provide ample power when needed.

Turbocharging technology perfectly met this need, and the "downsizing" concept was born.

1980s: The Golden Age of Performance

During this period, turbocharging became synonymous with high performance and speed.

Classic models such as the Porsche 911 Turbo, Saab 99 Turbo, and BMW 2002 Turbo brought turbocharging technology into the public eye.

They not only possessed powerful performance but also shaped an aggressive driving culture.

Companies like Garrett provided core turbocharging technology for many classic models during this period, establishing their industry leadership.

IV. Refinement and Innovation: Efficient and Environmentally Friendly Contemporary Solutions (Since the 21st Century) Entering the new century,

increasingly stringent emission regulations and environmental requirements transformed turbochargers from a "performance option" into a "necessity."

Technological Refinement

Variable Geometry Turbine (VGT/VNT): Primarily used in diesel engines, it effectively mitigates turbo lag by adjusting the turbine blade angle,

providing excellent boost performance across the entire rev range.

Twin-Scroll Turbo: Widely used in gasoline engines, it significantly improves turbo response speed by optimizing exhaust gas flow paths.

Electrical Control Technology and Materials Science: Advanced electronic control systems make turbine operation more precise and efficient.

Meanwhile, the application of new materials (such as high-temperature alloys) allows turbines to withstand higher operating temperatures,

significantly improving reliability.

Hybrid Power and Future Exploration

Today, turbochargers are combined with hybrid power systems to form more efficient powertrains.

The advent of electric turbochargers has completely solved the turbo lag problem—

using an electric motor to directly drive the turbine at low speeds, achieving instantaneous response. Looking to the future,

turbocharging technology will continue to be a key technology for achieving efficient and clean combustion in internal combustion engines,

and will develop in synergy with new energy power systems such as hydrogen fuel cells.

Summary

The development of turbochargers is a history of evolution from military aviation to civilian performance,

and then to environmental protection for all. It has evolved from a specialized device for raising aircraft

ceilings to an extreme weapon in motorsports, and ultimately to a core technology for billions of cars

worldwide to achieve a balance between energy efficiency and performance. As industry pioneers like Garrett have continued to drive,

the story of this century-old technology is far from over and continues to be written.